MECHANICAL TESTING

Mechanical testing of materials is generally required in structural applications but can serve as a process and product control mechanism in any industry. They are necessary to ascertain the intrinsic mechanical properties of a material.

The advantages provided by mechanical tests broadly fall into two categories:

- they establish standardised methodologies for the processing of the material

- they determine the quality of the material for the construction of an object

These tests compare the results obtained with the reference standards in order to evaluate the mechanical conformity of the tested materials.

These are utilised, among other things, to evaluate the correct execution of heat treatments, inspecting and verifying welding processes and welder competence.

The main mechanical tests which can be performed in our laboratories are:

- Tensile testing (cylindrical and flat)

- Load and compression testing

- Bend testing

- Impact testing (at room temperature and at low temperatures)

- Hardness and microhardness testing.

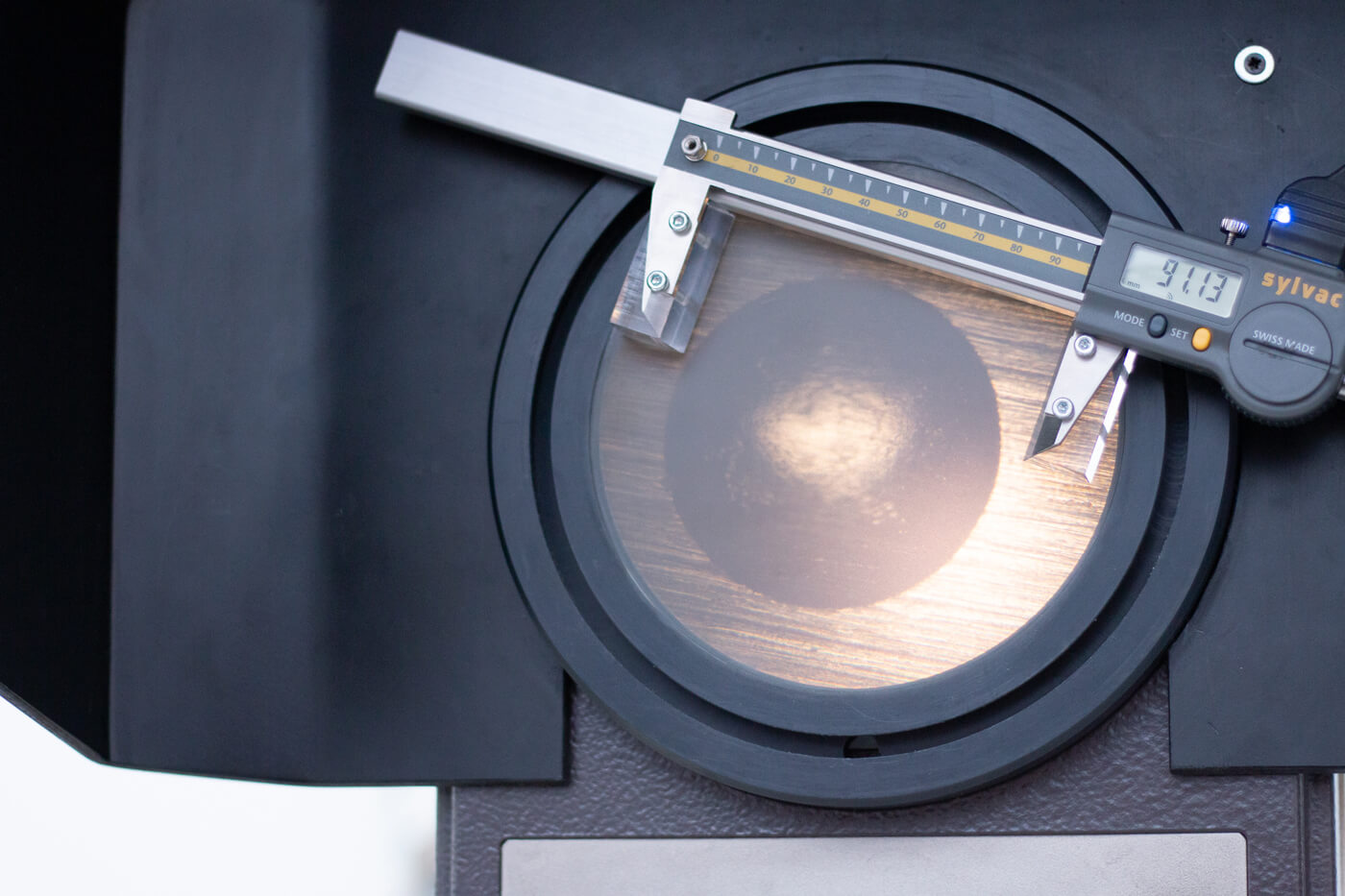

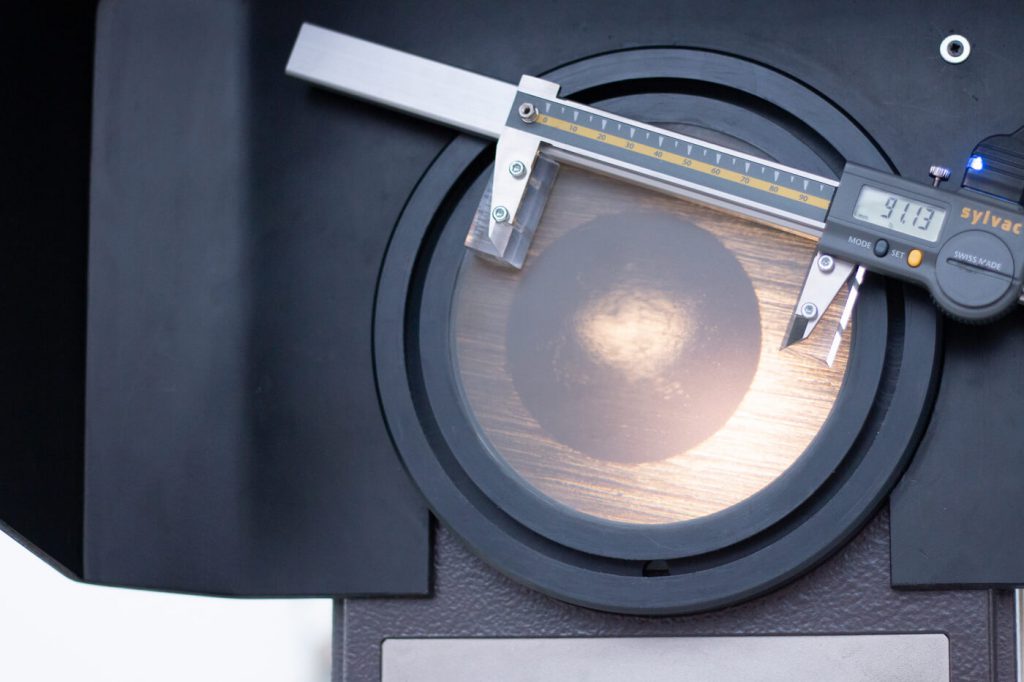

The preparation of the specimens for the mechanical tests takes place in our workshop within our laboratory, and is performed by highly specialised operators.