Corrosion testing

We can monitor the inevitable aging of your products.

Metallic samples, with or without coatings, are subjected to comparison corrosion tests (accelerated aging tests) in order to obtain information on corrosion resistance. The tests highlight the differences that different materials, processes, treatments and coatings (metallic and organic) have on the development of corrosion on the surface of tested materials. This method allows tests to be carried out on paints and coatings in general.

Nowadays, requests for these tests are increasingly being specified and standardised in a range of sectors including automotive, marine, white goods, components and precision mechanics.

Typical accelerated aging tests we can provide in Unilab are:

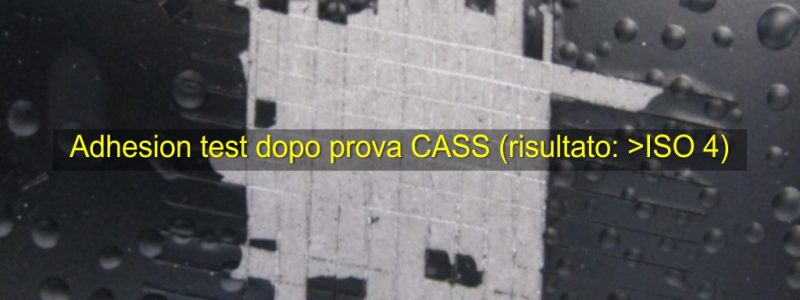

- “NSS”, “AASS”, and “CASS” Salt Spray Tests (UNI EN ISO 9227, ASTM B117)

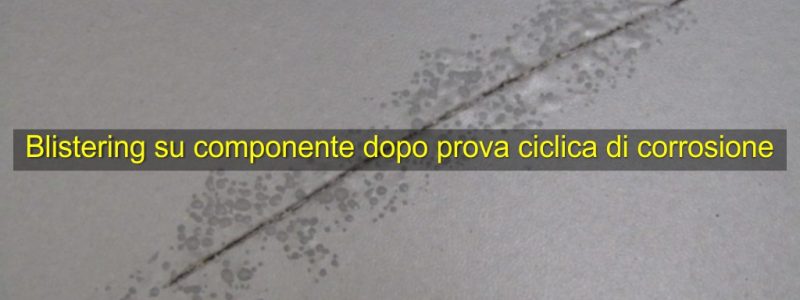

- Cyclical testing conducted according to our client’s specifications, a requirement typical of the automotive industry

- Static humidity chamber tests (UNI EN ISO 6270-1)

- Constant condensation tests (UNI EN ISO 6270-2)

- SWAAT Tests (ASTM G85:A3)

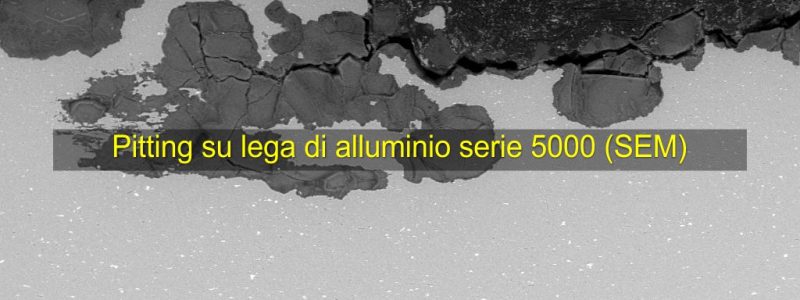

In addition to comparison tests, corrosion resistance evaluations can also be carried out by subjecting the materials to direct contact with chemical agents in controlled and standardised conditions of temperature, humidity and exposure with evaluation, for example, of the weight loss of standardised samples. This category of tests includes corrosion tests for susceptibility to pitting, and to intergranular corrosion in stainless steels (ASTM G48, ASTM A262).

The extensive expertise and equipment of Unilab Laboratori Industriali s.r.l. is at your disposal to perform the following inspections for the verification and prevention of corrosive phenomena:

- Salt spray tests.

- Static humidity chamber tests.

- Contact tests (with alkalis, acids, oils, detergents and a range of other fluids);

- Fluid Immersion tests of the part (generally acids), in accordance with the main European and International standards.

- Paint tests (cross-cut, thickness, pencil hardness, etc).

- Accelerated aging or mixed cycles of salt spray-climatic chambers (required in various regulations and internal specifications in the automotive sector.)