progetto Clean Production 2016

Coordinator: UNILAB Laboratori Industriali s.r.l.

Partners: Walvoil S.p.A., SIAP S.p.a., TMB S.p.A., Modine S.r.l., ZF Sachs, Orthofix S.r.l.

Primary objective: To develop advanced strategies for the application of “CLEAN” methodologies in companies

Beneficiaries: all participants and their direct customers

Possible financial support: Legislative Decree on Tax credits for Business networks

Project development and partners involved: autumn 2015

Project dates: February 2016 – January 2017

Abstract

Modern mechanical components and hydraulic systems are becoming ever more sophisticated, and as a consequence, more sensitive to environmental cleanliness. For this reason, the issue of Industrial Cleanliness is today considered a fundamental issue in industrial process management.

Designers of complex components introduce cleaning specifications into their designs, mainly through the use of an international ISO standard, (or equivalent methods) based on the functional requirements that the component is expected to fulfil. To meet this cleanliness requirement, the production area is forced to invest in facilities and to apply cleaning procedures (using washing machines, filtration and cleaning systems, and laboratory tests) which should be developed on the basis of strict technical standards or, at least, follow recognised international guidelines.

Each component considered – be it a solid part or a hydraulic fluid – is potentially a “dirt carrier” within the production chain. The task of the production engineer is to implement all possible actions to eliminate, or at least reduce the impact of any such contaminant. But investments in essential equipment, staff training, and laboratory equipment represent major obstacles to the implementation of these systems.

Leaving aside the economic aspects related to the investments necessary to address the issue at an industrial level, this project aims to resolve the two main critical aspects relating to the issue of Cleanliness:

- The industry-wide development of a Culture of Cleanliness through the provision of training and information initiatives and workshops aimed at sharing technical aspects and a range of industrial strategies

- The development of adequate technical procedures which can be applied to the production process, and which are capable of ensuring adequate levels of cleanliness monitoring in each phase of production.

This project therefore represents a prerequisite for companies that intend to make investments relating to the issue of Industrial Cleanliness.

The structure of the CLEAN PRODUCTION project focusses on two main objectives:

1) The provision and dissemination of information and training.

This objective is focused on training participants to understand customer requests, to assess how applicable to their product and, consequently, to be in a position to assess the costs associated with this application; it’s aim both at technical department staff members, where such specifications are included in the projects, and also at technical staff members responsible for evaluating cleanliness and implementing cleaning actions.

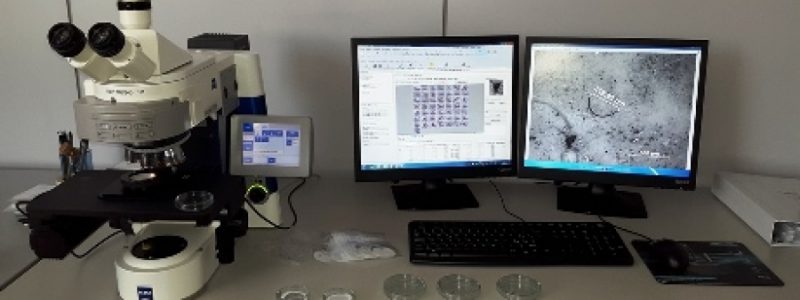

2) Consultancy and services.

The objective is to share with the participants the development of cleaning methodologies and/or laboratory facilities for the assessment of cleaning conditions. For participants who don’t foresee the need to equip themselves internally with analysis departments (Cleanliness laboratory), the project aims to develop and provide specific cleanliness tests specially developed according to the needs of the partners, for the entire duration of the project. The second edition of the project followed in 2017 with the aim of extending the study to further industrial sectors, and expanding the data base to new production areas, and we already have a list of companies who have confirmed their participation in the 2018 edition.

For further information please contact 0429/781280 or write to commerciale@unilab.it.