Clean production

Knowing that a component is not working because it’s dirty, without knowing why or how this dirt got there, doesn’t help solve the problem.

After more than five years of studies and analyses, in collaboration with multinational companies in the automotive sector, coupled with the carrying out of more than five thousand cleanliness tests in the laboratory, we’ve developed I-Clean, an effective method of production process intervention aimed at ensuring a client’s requirements are respected during the production processes.

To attain this, Unilab has achieved accreditation according to EN ISO/IEC 17025:2018 for carrying out ISO 16232:2018 testing and developed our I-Clean Method: to guarantee the efficiency and adequacy of industrial manufacturing processes.

The I-Clean Method is the culmination of a careful combination of the following activities:

Training: become a component cleaning specialist

- COMPONENT CLEANING COURSE: General aspects concerning the cleaning of components.

- ISO 16232 COURSE: Cleanliness testing according to EN-ISO 16232:2018.

- VDA19 COURSE The Automotive sector: the VDA19 standard parts 1 and 2.

- OIL CLEANLINESS COURSE: The cleanliness of hydraulic fluids.

- PRODUCTION CLEANING COURSE: The management of the cleaning of components on the production line.

- LABORATORY TEST 16232 COURSE: The laboratory cleanliness inspection. Technical support with examples of case histories

Consultancy: know your production process

- Inspection auditing of suppliers, with application of an evaluation checklist.

- Development of procedures, to improve cleanliness within a company.

- Consultancy, for the evaluation of specific cleanliness requirements for a sector.

- Inter-laboratory comparison to enable you to evaluate your in-house testing laboratory.

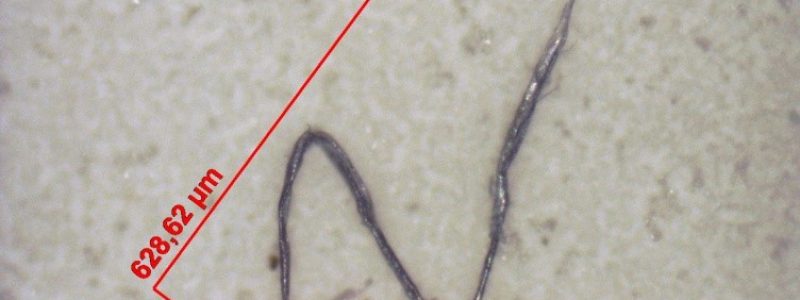

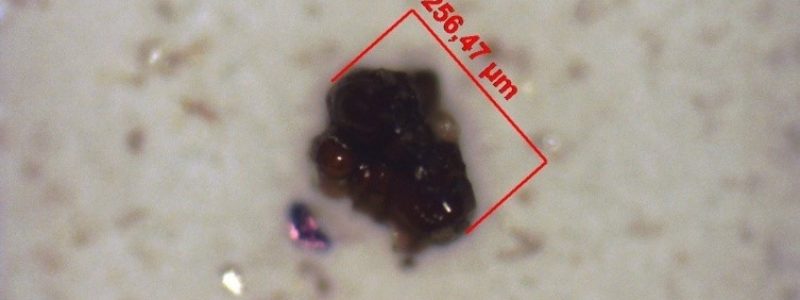

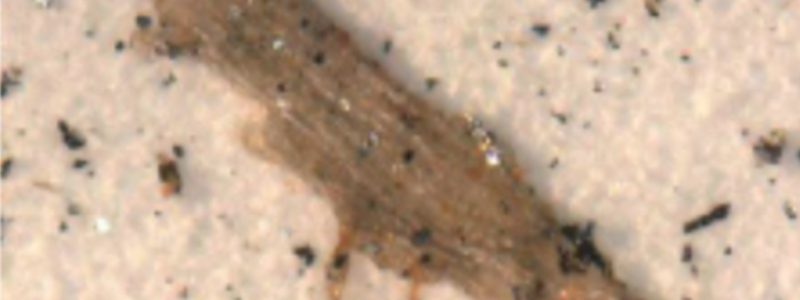

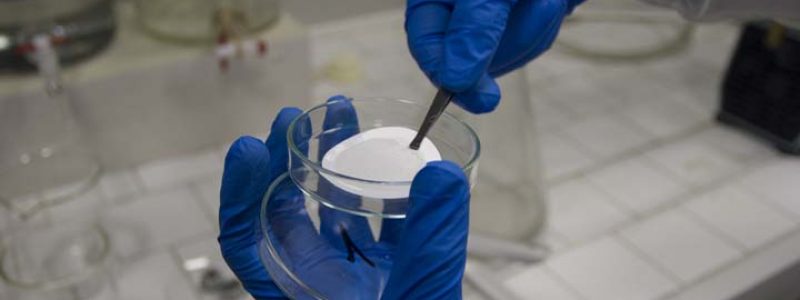

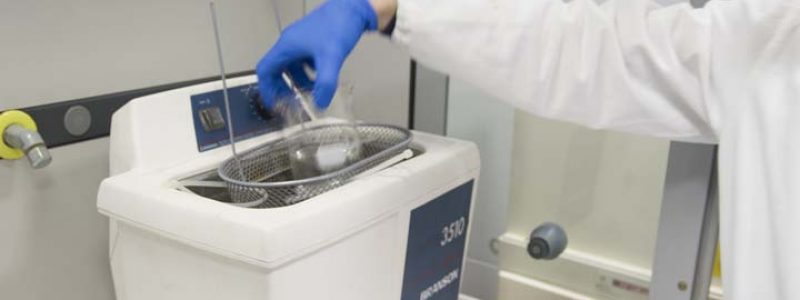

Laboratory tests: laboratory methodology for conducting cleanliness inspections on products

- Execution of cleanliness inspections according to the main market specifications.

- SEM + EDS analysis for the evaluation of the chemical nature of particles.

- Mapping of the level of cleanliness of production lines.

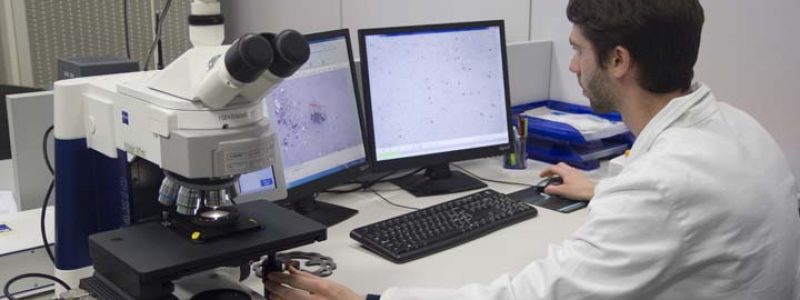

- Verification of the performance of the optical microscopy system (size and count).

Technical support: improving confidence in component cleanliness inspections

- Technical support to operators in the field of gravimetry, granulometry and particle counting measurements.

- Drafting of microscope analysis programs (only on the Zeiss SWC)

Sfoglia in questa pagina il nostro opuscolo I-CLEAN

Please wait while flipbook is loading. For more related info, FAQs and issues please refer to DearFlip WordPress Flipbook Plugin Help documentation.

Per ulteriori informazioni o delucidazioni in merito CONTATTACI!